Introduction

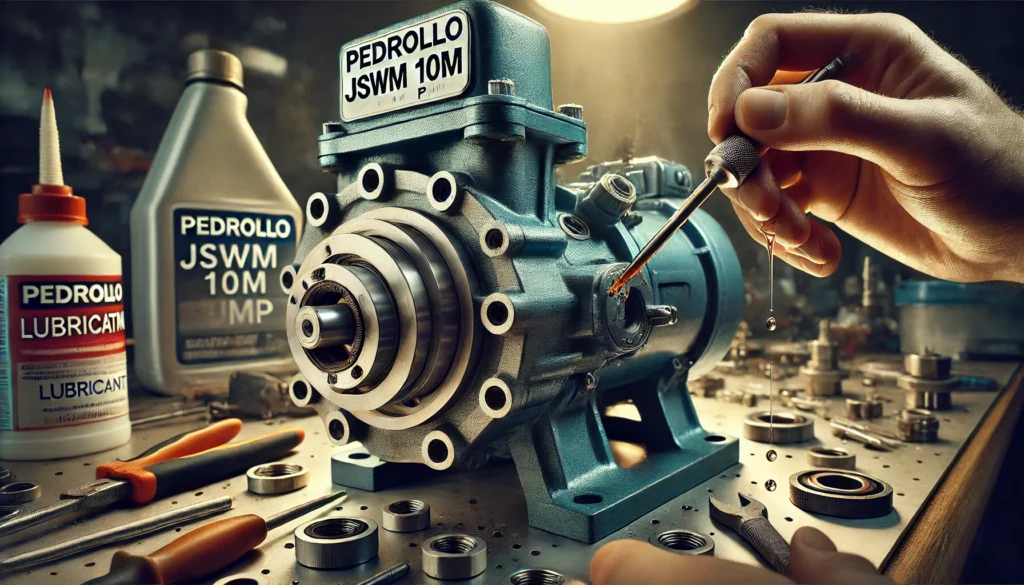

When it comes to water pumping systems, Pedrollo has established itself as a reliable brand known for producing high-quality pumps. The Pedrollo JSWM 10M pump is a popular model used in various applications such as draining water, irrigation, and transferring liquids. Proper lubrication and maintenance are crucial for ensuring that the pump operates efficiently and lasts longer.

In this blog post, we’ll guide you through the steps of lubricating and maintaining the Pedrollo JSWM 10M pump. This article will cover the types of lubrication needed, how to carry out regular maintenance, and tips for troubleshooting common issues. Whether you are a seasoned professional or a beginner, these guidelines will help you keep your pump running at its best.

Why Proper Lubrication is Important for Your Pedrollo Pump

The Role of Lubrication in Pump Performance

Lubrication plays a critical role in reducing friction between moving parts within the pump. Without proper lubrication, metal components can wear down more quickly, which can cause damage and decrease the efficiency of the pump. In the case of the Pedrollo JSWM 10M pump, which is designed for continuous operation, adequate lubrication ensures that the motor, bearings, and other internal parts run smoothly.

Lubricating the pump at regular intervals can also help to:

- Increase operational life: Well-lubricated components are less prone to wear and tear.

- Improve efficiency: Lubricated moving parts reduce friction, which leads to better performance and energy efficiency.

- Prevent overheating: Proper lubrication helps in the dissipation of heat, preventing the pump from overheating and suffering from thermal damage.

Components That Need Lubrication

In a Pedrollo JSWM 10M pump, the primary components that require lubrication are:

- Bearings: The bearings support the motor shaft and reduce friction during rotation. If not lubricated, the bearings can wear out, leading to a failure of the motor.

- Motor shaft: The shaft connects the motor to the pump impeller. This rotating part needs to be properly lubricated to avoid wear.

- Seals: Seals prevent leakage and need adequate lubrication to maintain their integrity.

It’s important to choose the right type of lubricant and apply it in the correct quantities, as this can significantly affect the pump’s lifespan.

Types of Lubricants for Pedrollo JSWM 10M Pump

Oil-Based Lubricants

Oil-based lubricants are commonly used for pumps like the Pedrollo JSWM 10M because they provide a thin, even coat of protection. These lubricants are ideal for reducing friction between rotating parts. Common oil-based lubricants include motor oil, machine oil, and specific pump oils available on the market.

Grease-Based Lubricants

Grease is another popular option for lubrication, especially for components that are exposed to water or moisture. Grease offers better adhesion to parts compared to oil, making it ideal for preventing rust and corrosion in pumps that operate in wet environments.

Lithium-based grease is a common grease type used in Pedrollo pumps as it works well under high temperatures and provides long-lasting lubrication.

Lubricating Oil for Pedrollo JSWM 10M

For the Pedrollo JSWM 10M pump, a high-quality water-resistant oil is usually recommended. Look for oils designed for high-efficiency pumps, ensuring they are safe to use in the pump’s motor and bearings. If you’re unsure about the type of oil to use, consult the pump’s manual or the manufacturer’s guidelines for the best recommendations.

Step-by-Step Guide to Lubricating Pedrollo JSWM 10M Pump

Step 1: Turn Off the Pump and Disconnect Power

Before you begin the lubrication process, make sure the pump is turned off and completely disconnected from its power source. This is a crucial safety step to avoid accidents during maintenance.

Step 2: Locate the Lubrication Points

Refer to the Pedrollo JSWM 10M pump manual to locate the lubrication points. Typically, you will find lubrication points around the bearings, motor shaft, and seals. Some models may have specific ports for adding oil or grease, so take note of their exact locations.

Step 3: Clean the Pump

Before adding new lubricant, it’s essential to clean the lubrication points. Use a clean cloth to wipe off any dirt, debris, or old lubricant. This prevents contaminants from mixing with the new lubricant and ensures that the lubrication points are clean and functioning effectively.

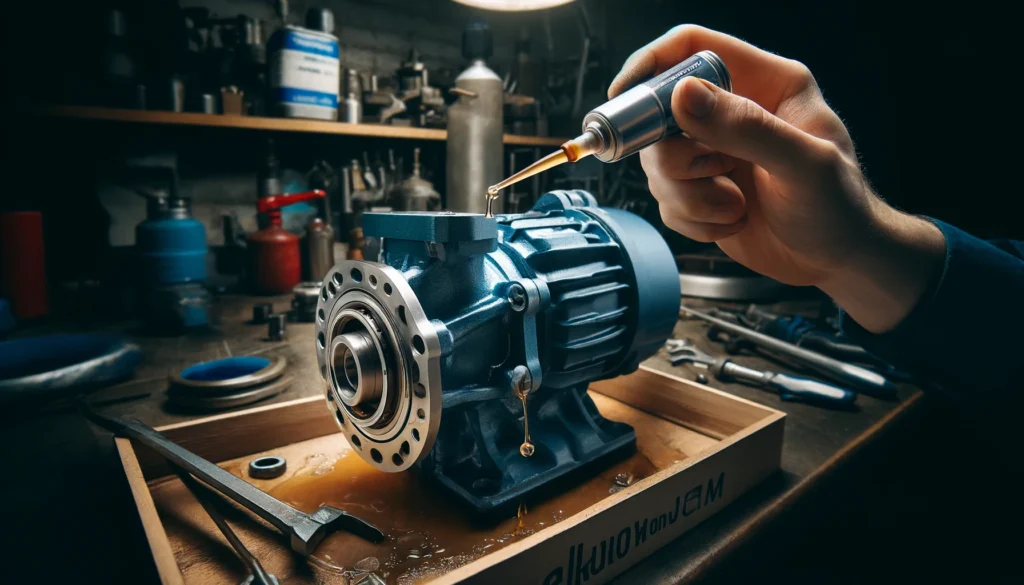

Step 4: Apply Lubricant

- For oil: Use an oil can or a lubricant pump to add oil into the designated ports. Add the lubricant slowly and in small quantities until the oil level reaches the recommended amount. Avoid overfilling, as this can cause leaks or damage to the pump.

- For grease: Apply the grease to the bearings and seals using a grease gun or a hand applicator. Ensure an even distribution of the grease, and avoid excessive application, as this can lead to unnecessary buildup.

Step 5: Reassemble and Test the Pump

After the lubrication has been applied, reassemble the parts and make sure everything is secure. Turn on the pump and allow it to run for a few minutes to ensure that the lubricant is circulating properly. Listen for any unusual sounds or vibrations that may indicate an issue with the lubrication or pump performance.

Regular Maintenance for Pedrollo JSWM 10M Pump

Lubrication is just one part of maintaining the Pedrollo JSWM 10M pump. To ensure the longevity and smooth operation of your pump, here are additional maintenance tips to follow:

Check for Leaks

Regularly inspect the pump for any signs of oil or water leakage. Leaks can indicate damaged seals or improper lubrication, and they should be addressed immediately to prevent further damage.

Clean the Pump Regularly

Dirt and debris can accumulate on the pump over time, affecting its efficiency. Clean the external parts of the pump regularly to prevent clogging. Use a soft cloth and water to wipe down the pump. Avoid harsh chemicals that could damage the pump’s components.

Inspect the Motor and Shaft

Check the motor and shaft for signs of wear or damage. If the motor is making unusual noises or if the shaft appears misaligned, it may require attention from a professional.

Monitor Performance

Keep an eye on the pump’s performance, especially during peak usage. If you notice a drop in water pressure, unusual vibrations, or overheating, it may be a sign that the lubrication has worn off or the pump needs repair.

Troubleshooting Common Issues with Pedrollo JSWM 10M Pump

Despite proper lubrication and maintenance, you might face some common issues with your Pedrollo JSWM 10M pump. Here are a few troubleshooting tips:

Pump Not Starting

- Possible Cause: Low or no lubrication, or a malfunctioning motor.

- Solution: Check the lubrication level and add oil or grease if necessary. If the motor is still not working, it might need professional inspection.

Pump Running Noisily

- Possible Cause: Insufficient lubrication, worn bearings, or debris inside the pump.

- Solution: Lubricate the pump components and clean any debris inside the motor housing. If the noise persists, the bearings may need to be replaced.

Pump Overheating

- Possible Cause: Excessive friction due to inadequate lubrication, or overloading the pump.

- Solution: Lubricate the motor and bearings properly and ensure the pump is not overloaded beyond its capacity.

Conclusion

Proper lubrication is essential for the optimal performance and longevity of the Pedrollo JSWM 10M pump. Regularly applying the right type of lubricant to key components like the bearings, motor shaft, and seals ensures smooth operation, increased efficiency, and prolonged life of the pump. Alongside lubrication, ongoing maintenance—such as cleaning, checking for leaks, and inspecting the motor—is vital to keep the pump in top shape.

By following the guidelines in this article, you can ensure that your Pedrollo JSWM 10M pump operates efficiently and continues to serve your needs for years to come. Remember to always consult the manufacturer’s manual for specific recommendations, and when in doubt, don’t hesitate to seek professional help for maintenance or repairs.

Taking these small steps in maintenance will make a big difference in the performance and durability of your water pump!

FAQs

1. Why is lubrication important for the Pedrollo JSWM 10M pump?

Lubrication is essential for reducing friction between the moving parts of the Pedrollo JSWM 10M pump, such as the motor shaft and bearings. Proper lubrication helps prevent wear and tear, improves efficiency, and extends the life of the pump. It also prevents overheating and ensures smooth operation.

2. What type of lubricant should I use for the Pedrollo JSWM 10M pump?

For the Pedrollo JSWM 10M pump, you should use high-quality water-resistant lubricants. Both oil-based and grease-based lubricants are suitable, depending on the specific components. Oil is ideal for moving parts like the motor shaft and bearings, while grease is better for seals and areas exposed to moisture.

3. How often should I lubricate my Pedrollo JSWM 10M pump?

The frequency of lubrication depends on how often the pump is used. As a general guideline, it’s advisable to lubricate the pump every 3 to 6 months if it’s used regularly. However, if the pump is in continuous operation, or if you notice unusual noises or overheating, more frequent lubrication may be necessary.

4. Can I over-lubricate my Pedrollo JSWM 10M pump?

Yes, over-lubricating can cause excess lubricant to leak out and create messes or clogging. It can also lead to increased friction and pressure within the pump. Always follow the manufacturer’s recommended lubricant quantity to avoid overfilling.

5. What are the main parts of the Pedrollo JSWM 10M pump that need lubrication?

The primary parts of the Pedrollo JSWM 10M pump that need lubrication are:

- Bearings: These support the motor shaft and reduce friction during operation.

- Motor shaft: It connects the motor to the impeller and needs lubrication to prevent wear.

- Seals: Lubrication helps maintain the integrity of seals, preventing leakage and ensuring efficient operation.

6. How can I tell if my Pedrollo JSWM 10M pump needs lubrication?

Signs that your Pedrollo JSWM 10M pump needs lubrication include:

- Unusual noises, such as squeaking or grinding.

- Decreased water flow or pressure.

- Overheating of the pump during operation.

- Increased vibration or reduced motor performance.

If you notice any of these issues, it’s a good idea to check the lubrication levels and apply fresh lubricant as needed.

8. Can I use any oil or grease for my Pedrollo JSWM 10M pump?

It’s essential to use the right type of oil or grease recommended by the manufacturer for the Pedrollo JSWM 10M pump. Look for high-quality water-resistant oils and lithium-based greases, as they offer better protection against moisture and high temperatures. Always consult the user manual for specific lubricant recommendations.

9. Can I lubricate the Pedrollo JSWM 10M pump myself, or do I need professional help?

You can generally lubricate the Pedrollo JSWM 10M pump yourself by following the steps outlined in the manual. However, if you are unsure or uncomfortable performing maintenance, or if your pump requires more advanced repairs, it’s always a good idea to contact a professional for assistance.

10. How long does lubrication last in the Pedrollo JSWM 10M pump?

Lubrication can last anywhere from 3 to 6 months, depending on the usage of the pump. In high-use environments, it may need to be reapplied more frequently. Always monitor the performance of the pump, and reapply lubrication if you notice any issues such as increased noise or friction.

11. What should I do if I accidentally spill lubricant on my Pedrollo JSWM 10M pump?

If lubricant is spilled, immediately wipe it off with a clean cloth to prevent it from attracting dirt or creating slippery surfaces. Be sure to also inspect the surrounding components to ensure no debris has entered the pump. Spilled lubricant can cause clogs, so it’s essential to keep the pump clean.